We Work Strictly And Responsibly.

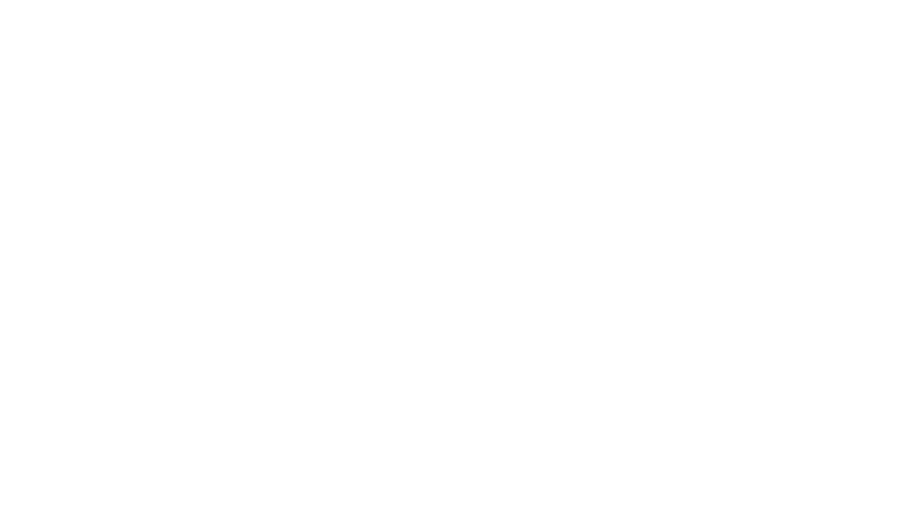

Step 01: Customer Requirement Analysis

Feasibility Study

Material & Specification Evaluation

Resource Planning

Timeline & Cost Estimation

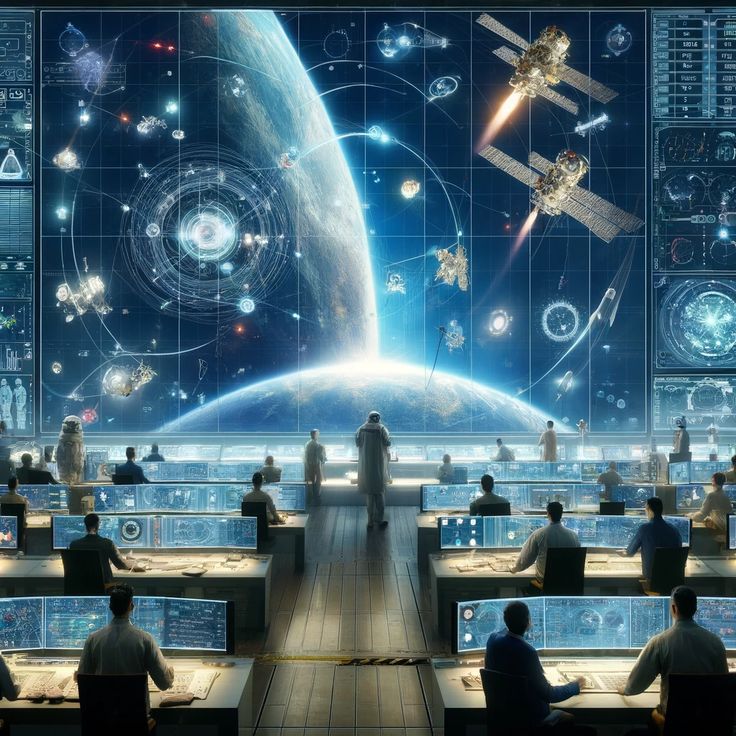

Step 02:Engineering & Design Validation

Design Interpretation and Design for Manufacturability - DFM

Tolerance Stack Up Analysis

Fixture and Tool Design

Process Planning and Route Card Generation

Software Expertise: CATIA, SolidWorks, AutoCAD, and other advanced CAD/CAM tools for precision aerospace design and engineering.

Step 03: Procurement & Material Management

AS 9100 & ISO Certified Vendors

Incoming Inspection & Mill TC Verification

Inventory Management through our ERP Systems

Strategic Sourcing for Long Lead Items

ERP Systems • FTP Solutions • Storage Infrastructure

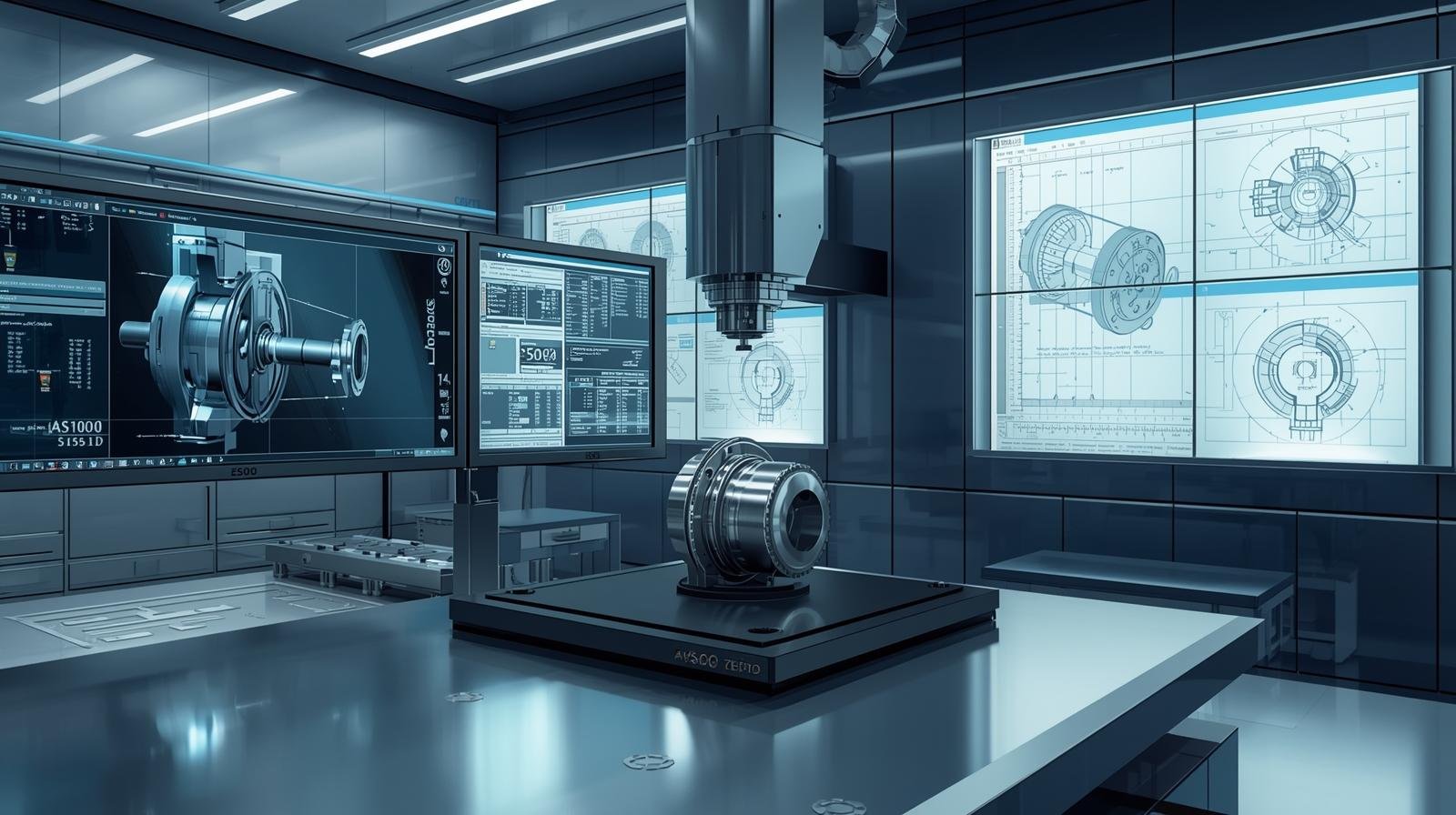

Step 04: Precision Manufacturing

At each of our specialized units, we execute:

CNC Machining (3,4,5th-axis) – (Halamanee Aerospace Pvt Ltd – 2 Entities)

Wire EDM, Sparking - (Halamanee Precisions)

Sheet Metal Manufacturing

Aerostructures Assemblies and their sub-assemblies - (Halamanee Aerostructures Pvt Ltd)

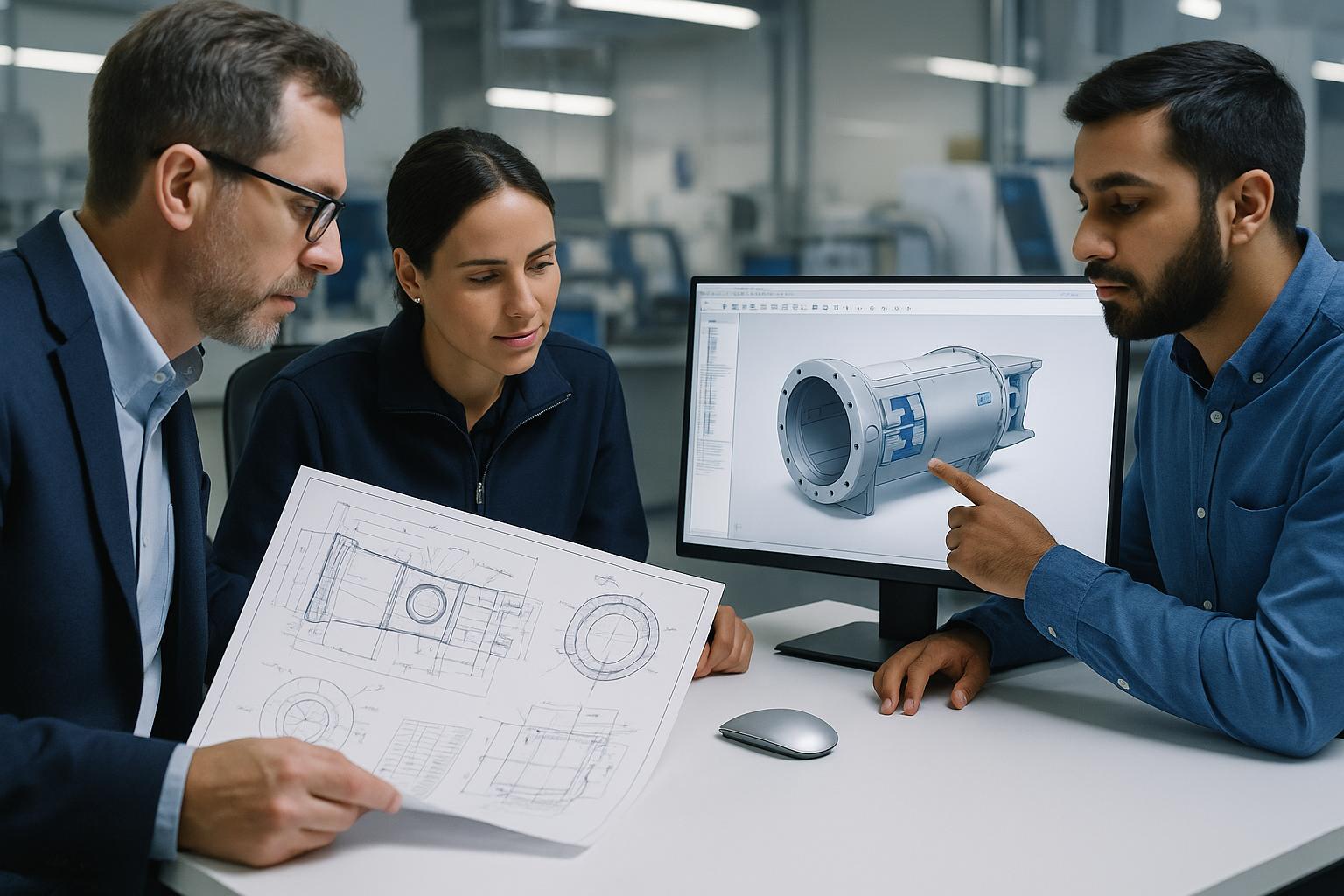

Step 05:In-Process Quality Control

First Article Inspection (FAI)

In-process & Final Dimensional Checks

CMM – Carl Zeiss Contura G2

Root Cause Analysis for Any Deviations

Step 06: Final Inspection, Documentation

100% Final Dimensional Inspection

Visual Inspection and through Highly advanced quality assurance equipment

Documentation: PPAP, COC, FAIR, QC Report

Packing as per Aerospace Standards

Step 07: Dispatch & Client Delivery

Custom Crating & Export-Grade Packing

Logistic Coordination

On-Time Delivery Assurance

Customer Acknowledgment & Feedback Loop

Step 08: Post-Dispatch Support

Performance Feedback Analysis

Regular evaluation of delivered parts and assemblies to measure consistency, reliability, and field performance.

Continuous Improvement Programs (Kaizen, Six Sigma)

Driving operational excellence by minimizing defects, optimizing processes, and enhancing efficiency.

Design Change Support

Partnering with customers for design upgrades, ensuring smooth transitions while maintaining compliance with aerospace standards.

Long-Term Vendor Development Initiatives

Strengthening partnerships with suppliers to ensure sustainability, reliability, and global competitiveness.