Shaping the Future: Emerging Technologies in Aerospace & Defense.

The aerospace and defence sector is evolving faster than ever, driven by technological breakthroughs that demand precision, reliability, and efficiency. At Halamanee Aerospace, we continuously invest in state-of-the-art infrastructure and processes to stay ahead of this transformation.

From 5-axis CNC machining and advanced wire EDM to ERP-enabled traceability systems, we integrate cutting-edge tools that ensure accuracy and consistency at every stage. Our engineering teams leverage CAD/CAM simulation, tolerance analysis, and design for manufacturability (DFM) to translate complex designs into manufacturable, high-quality components.

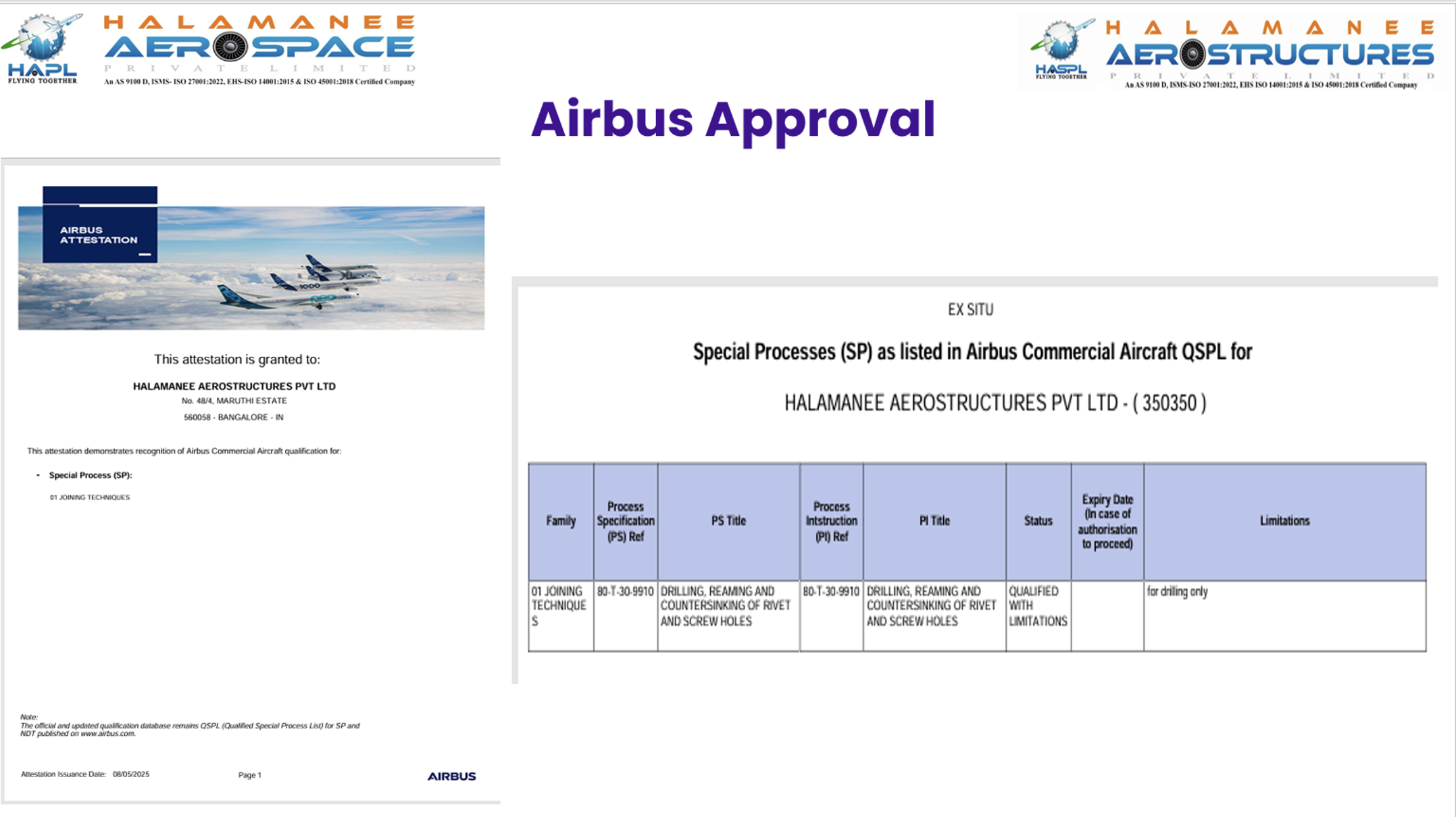

What sets us apart is our ability to align emerging technologies with global aerospace standards such as AS9100D, Airbus approvals, and ISO certifications. This ensures that our clients not only receive parts of unmatched precision but also benefit from reduced cycle times, optimized costs, and reliable supply chains.

Technology is not just about machines—it is about enabling partnerships, improving efficiency, and meeting the future of aerospace and defence with confidence.

India’s SMEs: The Backbone of the Global Aerospace Supply Chain.

Over the past decade, India has established itself as a key contributor to the global aerospace ecosystem. At the heart of this transformation are Small and Medium Enterprises (SMEs) that provide agility, cost competitiveness, and innovation.

Halamanee Aerospace is proud to be one of these SMEs, recognized as an Airbus-approved supplier and trusted partner to several global aerospace and defence majors. With in-house infrastructure across specialized units, a team of over 200 trained professionals, and ERP-based workflows, we have proven that Indian SMEs can deliver at par with international benchmarks.

By combining precision manufacturing, strict quality control, and sustainable practices, we play a vital role in strengthening global supply chains. Our contributions extend beyond aerospace, supporting defence, medical, oil & gas, and space sectors—making us a versatile and dependable partner.

The rise of Indian SMEs is not just a regional success story; it is a global shift in how supply chains are built. At Halamanee Aerospace, we are proud to be part of this movement.

From Precision Machining to Aerostructures: An Integrated Manufacturing Journey.

The aerospace industry demands more than just components—it demands systems, assemblies, and integration at scale. At Halamanee Aerospace, we have evolved from precision tooling and machining to the assembly of complex aerostructures and sub-assemblies, offering a complete manufacturing ecosystem.

Our specialized units handle everything from CNC machining (3,4,5-axis) and EDM operations to sheet metal forming and aerostructure assemblies. Backed by AS9100D-certified processes and advanced quality systems like CMM inspections and First Article Inspections (FAI), we ensure zero-compromise delivery.

This integrated approach allows us to be a one-stop solution provider—simplifying supply chains, reducing lead times, and supporting customers through the entire lifecycle from design validation to final assembly.

It’s not just about parts—it’s about building solutions that power aircraft, defence platforms, satellites, and medical systems across the globe.

Global Standards, Local Excellence: The Value of Aerospace Certifications & Approvals.

In aerospace, trust is built on certification. Global OEMs rely on suppliers that meet stringent international standards, ensuring safety, reliability, and compliance.

At Halamanee Aerospace, our commitment to quality is reinforced by multiple global certifications, including AS9100D, ISO 9001, ISO 14001 (EMS), ISO 45001 (EOHS), and ISO 27001 (ISMS). As an Airbus-approved supplier, we proudly demonstrate that Indian manufacturers can deliver at par with the world’s best.

These certifications are more than just paperwork—they represent our dedication to process discipline, quality assurance, and continuous improvement (Kaizen, Six Sigma). They assure customers that every product manufactured by us undergoes rigorous inspections, documentation (PPAP, FAIR, COC), and traceability controls.

For clients, this means reduced risk, guaranteed compliance, and the confidence that every part we deliver meets the highest global aerospace benchmarks.

Sustainability in Aerospace: Driving Quality, Efficiency, and Responsibility.

The aerospace industry is entering an era where sustainability is just as important as precision. Global supply chains are demanding eco-conscious practices that reduce environmental impact without compromising quality.

At Halamanee Aerospace, sustainability is woven into our operations. Through ISO 14001 (Environmental Management Systems), lean manufacturing principles, and responsible resource management, we ensure that our processes are environmentally responsible and energy-efficient.

Sustainability also means waste reduction, defect elimination, and continuous improvement (Kaizen, Six Sigma)—all of which improve efficiency while lowering costs for our clients. By adopting eco-friendly surface treatments, optimized procurement, and smart logistics, we help shape a greener future for aerospace and defence.

In today’s world, sustainability is not optional—it is a commitment to future generations. By combining quality excellence with environmental responsibility, Halamanee Aerospace stands as a trusted, forward-thinking partner to global industries.